We are providing wide range of whole tyre reclaim rubber and these are quality tested at our quality testing unit. With high quality standard and strict quality control system, these range meet the international standard. Extensive Refined Reclaim Rubber obtained by reclamation from scrap tyre. High tensile,High Mooney / Low Mooney reclaimed rubber and Special grade reclaimed rubber as per customer specification can be provided.

MATERIAL CHARACTERIZATION

APPEARANCE : BLACK SLAB 0.5 to 0.75 Inch thick

COLOUR : BLACK

TENSILE STRENGTH : GOOD TENSILE AND AGEING PROPERTIES, FREE FROM FIBROUS / METALIC MATERIALS, BLENDED WHOLE TYRE RECLAIM. HIGH TENSILE, MAXIMUM REFINING TO GIVE SMOOTH APPEARANCE

PACKING : 50 KG HDPE BAGS, LABLE IN BLUE INK OR Tied with Carristrap in bare packing

MARKING : NAME OF MATERIAL/ OUR DETAILS/ DATE OF MFG/ GRADE CODE / QTY

MK-01-HT SUPERFINE GRADE – HIGH TENSILE

Item Description: Reclaimed Rubber – WTR-HT Grade: MK – 01 HT (Superfine)

| No | Particulars | TARGET | MIN | MAX | METHOD |

|---|---|---|---|---|---|

| 1 | Ash Content (%) | 7.0 | 4.0 | 09.0 | IS 6306-1971 |

| 2 | Acetone Extract (%) | 14.0 | 9.0 | 18.0 | IS 6306-1971 |

| 3 | Carbon Black (%) | 26.0 | 22.0 | 30.0 | IS 6306-1971 |

| 4 | Rubber Hydro Carbon (%) | ---- | 45.0 | ----- | IS 6306-1971 |

| 5 | Specific gravity (gm/cm³) | 1.15 | 1.10 | 1.20 | IS 6306-1971 |

| 6 | Mooney Viscosity ML(1+4)@100ºC | 30.0 | 20.0 | 45.0 | IS 6306-1971 |

| 7 | Tensile Strength (PSI) | 900.0 | 800.0 | ---- | IS 3400-1987 |

| 8 | Elongation at Break(%) | --- | 180.0 | ---- | IS 3400-1987 |

| 9 | T5 | 5.50 | 4.50 | ---- | ASTM D 1646 |

| 10 | Volatile matter (%) | --- | --- | 1.10 | IS 6306-1971 |

MK – 01 SUPERFINE GRADE

Item Description: Reclaimed Rubber – WTR Grade: MK – 01 (Superfine)

Item Description: Reclaimed Rubber – WTR Grade: MK – 01 (Superfine)

| No | Particulars | TARGET | MIN | MAX | METHOD |

|---|---|---|---|---|---|

| 1 | Ash Content (%) | 7.0 | 4.0 | 09.0 | IS 6306-1971 |

| 2 | Acetone Extract (%) | 14.0 | 9.0 | 18.0 | IS 6306-1971 |

| 3 | Carbon Black (%) | 26.0 | 22.0 | 30.0 | IS 6306-1971 |

| 4 | Rubber Hydro Carbon (%) | ---- | 45.0 | ----- | IS 6306-1971 |

| 5 | Specific gravity (gm/cm³) | 1.15 | 1.10 | 1.20 | IS 6306-1971 |

| 6 | Mooney Viscosity ML(1+4)@100ºC | 30.0 | 20.0 | 45.0 | IS 6306-1971 |

| 7 | Tensile Strength (kg/cm²) | 45.0 | 40.0 | ---- | IS 3400-1987 |

| 8 | Elongation at Break(%) | --- | 180.0 | ---- | IS 3400-1987 |

| 9 | T5 | 5.50 | 4.50 | ---- | ASTM D 1646 |

| 10 | Volatile matter (%) | --- | --- | 1.10 | IS 6306-1971 |

MK – 02 FINE GRADE

Item Description: Reclaimed Rubber – WTR Grade:MK – 02 (Fine)

| No | Particulars | TARGET | MIN | MAX | METHOD |

|---|---|---|---|---|---|

| 1 | Ash Content (%) | 7.0 | 4.0 | 09.0 | IS 6306-1971 |

| 2 | Acetone Extract (%) | 14.0 | 9.0 | 18.0 | IS 6306-1971 |

| 3 | Carbon Black (%) | 26.0 | 22.0 | 30.0 | IS 6306-1971 |

| 4 | Rubber Hydro Carbon (%) | ---- | 45.0 | ----- | IS 6306-1971 |

| 5 | Specific gravity (gm/cm³) | 1.15 | 1.10 | 1.20 | IS 6306-1971 |

| 6 | Mooney Viscosity ML(1+4)@100ºC | 30.0 | 20.0 | 45.0 | IS 6306-1971 |

| 7 | Tensile Strength (kg/cm²) | 45.0 | 40.0 | ---- | IS 3400-1987 |

| 8 | Elongation at Break(%) | --- | 180.0 | ---- | IS 3400-1987 |

| 9 | T5 | 5.50 | 4.50 | ---- | ASTM D 1646 |

| 10 | Volatile matter (%) | --- | --- | 1.10 | IS 6306-1971 |

MK – 03 MEDIUM GRADE

Item Description: Reclaimed Rubber – WTR Grade:MK – 03 (Medium)

Item Description: Reclaimed Rubber – WTR Grade:MK – 03 (Medium)

| No | Particulars | TARGET | MIN | MAX | METHOD |

|---|---|---|---|---|---|

| 1 | Ash Content (%) | 7.0 | 6.0 | 10.0 | IS 6306-1971 |

| 2 | Acetone Extract (%) | 14.0 | 9.0 | 18.0 | IS 6306-1971 |

| 3 | Carbon Black (%) | 26.0 | 22.0 | 30.0 | IS 6306-1971 |

| 4 | Rubber Hydro Carbon (%) | ---- | 40.0 | ----- | IS 6306-1971 |

| 5 | Specific gravity (gm/cm³) | 1.15 | 1.10 | 1.20 | IS 6306-1971 |

| 6 | Mooney Viscosity ML(1+4)@100ºC | ---- | 30.0 | 55.0 | IS 6306-1971 |

| 7 | Tensile Strength (kg/cm²) | ---- | 35.0 | ---- | IS 3400-1987 |

| 8 | Elongation at Break(%) | --- | 130.0 | ---- | IS 3400-1987 |

| 9 | T5 | ---- | ---- | ---- | ASTM D 1646 |

| 10 | Volatile matter (%) | ---- | --- | 1.10 | IS 6306-1971 |

MK – 04 COARSE GRADE

Item Description: Reclaimed Rubber – WTR Grade:MK – 04 (Coarse)

Item Description: Reclaimed Rubber – WTR Grade:MK – 04 (Coarse)

| No | Particulars | TARGET | MIN | MAX | METHOD |

|---|---|---|---|---|---|

| 1 | Ash Content (%) | 7.0 | 6.0 | 10.0 | IS 6306-1971 |

| 2 | Acetone Extract (%) | 14.0 | 9.0 | 18.0 | IS 6306-1971 |

| 3 | Carbon Black (%) | 26.0 | 22.0 | 30.0 | IS 6306-1971 |

| 4 | Rubber Hydro Carbon (%) | ---- | 40.0 | ----- | IS 6306-1971 |

| 5 | Specific gravity (gm/cm³) | ---- | ---- | ---- | IS 6306-1971 |

| 6 | Mooney Viscosity ML(1+4)@100ºC | ---- | 30.0 | 55.0 | IS 6306-1971 |

| 7 | Tensile Strength (kg/cm²) | ---- | 35.0 | ---- | IS 3400-1987 |

| 8 | Elongation at Break(%) | --- | 130.0 | ---- | IS 3400-1987 |

| 9 | T5 | ---- | ---- | ---- | ASTM D 1646 |

| 10 | Volatile matter (%) | ---- | ---- | 1.10 | IS 6306-1971 |

APPLICATION

Reclaim rubber widely used in Truck Tyres, Tread Rubber and Rubber Moulded Components. Moderately refined reclaim rubber mainly used in Cycle Tyres, Rubber Mat, Battery Containers and also in molded rubber products. Coarse reclaim rubber mainly used in Tyre Flaps, Mats, Pedal Rubber, Rubber Sheets Floor/ Coir Matt etc…

ADVANTAGES

• Shorter and faster mixing cycles.

• Improved die swell, adhesion, permeability.

• Reduction in consumption of electrical power due to nerve of compound and faster mixing cycle.

• Practically no reduction in hot air ageing properties.

• Fewer compounds at less cost.

• Low calendaring and extrusion temperature.

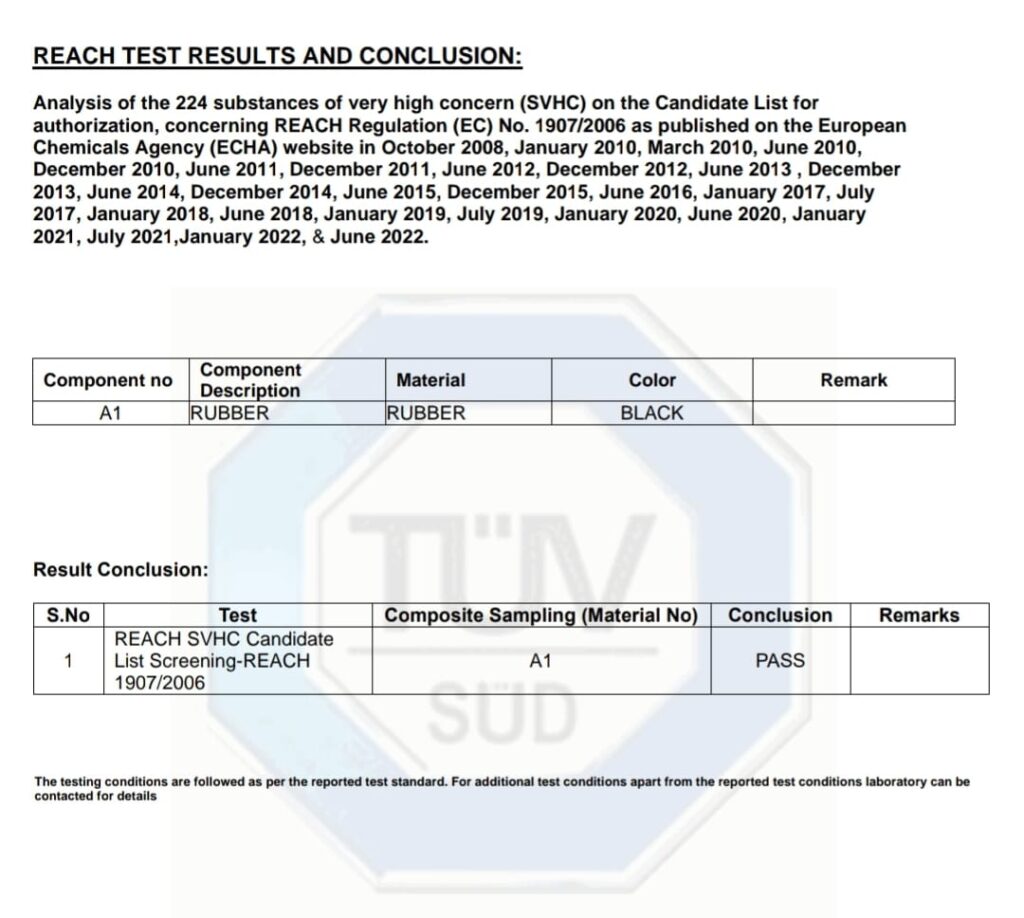

MKR-01 REACH Compliant Reclaimed Rubber

MKR-01 is our special grade for Reach compliant reclaimed rubber. We can supply all grades and many types of reclaimed rubber suitable for European market, based on your requirements.